Home > Products > Power Team Hydraulic Tools > Hydraulic Cylinder Selection

The Power Team range of hydraulic cylinders offers a large variety of sizes, capacities and functions. This means that MacScott Bond is likely to have the cylinder that is right for your application. However, the choice may seem daunting. Please see below our advice for selecting your cylinder. Remember if you are struggling to decide what you need with your cylinder please contact MacScott Bond for some assistance.

Tel:0131 448 2950

Considerations:

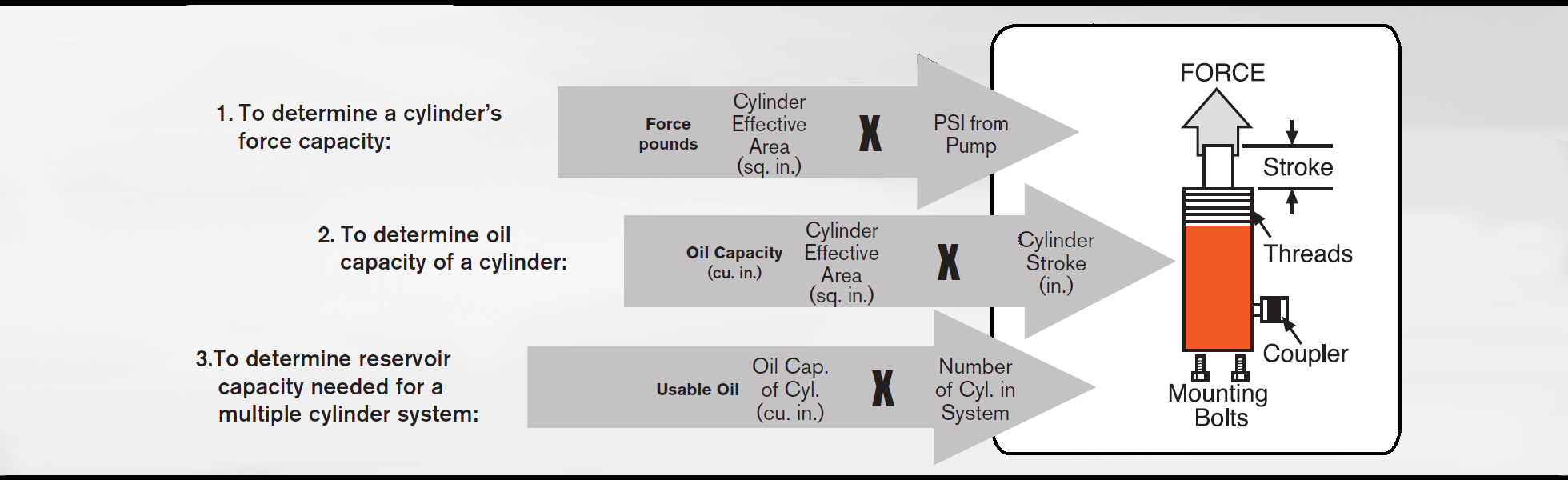

1. What push or pull tonnage is required per cylinder in your application? (20% more than what is required to lift the load)

2. What is the push or pull stroke length required?

3. Does the cylinder need to push, pull or both? (single-acting cylinders extend the piston under hydraulic pressure; double-acting cylinders extend and retract the piston under pressure.

4. Does the application require multiple cylinders?

5. Is the application stationary, or must the components be lightweight for ease of portability?

6. Do you need to extend a rod or cable through the centre of the cylinder for the application as in tensioning?

7. Does the application require that the cylinder fit within limited-clearance work areas?

8. Does the application require that the cylinder be "dead-ended" at the end of it's work stroke?

9. Will the cylinder need to withstand off-centre loads? Cylinders with swivel caps are available.

10. Does the application require that the lifted load be supported for extended periods of time? Locking collars are ideal for such jobs, as are cribbing blocks.

11. Is corrosion resistance required? Power Team's "Power Tech" surface treatment is standard on many of their cylinders, and optional on many of the steel constructed cylinders.

12. Will the application involve high cycles (over 2,500 in the cylinder's lifetime)? Ideal choices are the RD, RH, RP and the C series.

Cylinder Selection Charts

Power Team build their range of cylinders in their ISO 9001 registered manufacturing facility.

All Power Team cylinders are date coded, and stamped with a maximum pressure rating and capacity. Each cylinder made complies with the demanding ASME B30.1 standard and are pressure tested to 125% of capacity before leaving the factory.

Some other features included:

• Cylinder bores are roller burnished to harden and smooth the surface, improving seal life by 30%.

• Base mounting holes withstand full cylinder capacity.

• Typical cylinder burst pressure range is from 25,000 to 35,000 psi, wellbeyond extreme usage.

• Cylinders with gland nuts may be “ dead-ended” at 10,000 psi and are assembled/tested by certified assemblers.

• Eddy current and mag particle inspections detect flaws in the steel.

• Cylinder bodies are solid steel or aluminum, not welded like some competitive cylinders.

• Material is removed from surface to assure that any flaws are removed.

MacScott Bond Ltd is a member of the MacTaggart Scott Group. The Loanhead Division, certified to ISO9001: 2008 and OHSAS 18001:2007, has a full design, manufacture, installation, service and repair capability for pneumatic, oil or water hydraulic and cooling systems. We sell hydraulic, pneumatic and associated components and are distributors for SPX, Globe, Atlas Copco, SPX Power Team, MP Filtri, ACE controls and more.

Please feel free to contact our sales team or one of our engineers for more information about how MacScott Bond can help you.