Home > Engineering > Design and Manufacturing > Unmanned Flushing Rigs

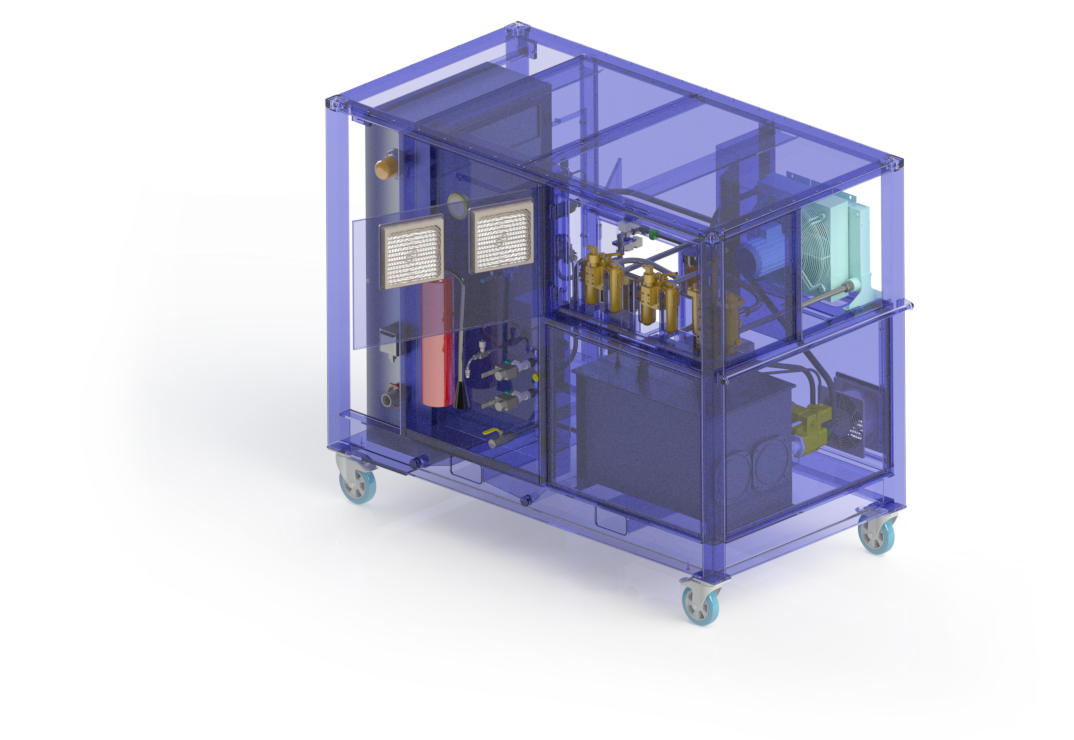

Flushing pipework is a demanding process. These new flushing rigs have been designed for safe unmanned operation with optimised flushing.

Oil is filtered via four duplex filters. An inline contamination monitor supplies test results to the systems PLC. When three consecutive passes have been achieved, with turbulent flow, beacons flash alerting shop floor flushing is complete.

To achieve safe unmanned flushing the PLC controls or monitors include:

Reservoir oil level

Flow

Hot oil temperature control

Inlet pressure

Filter condition

Contamination level

Options:

Flow switching

Pressure compensated pump

Triple pump with basic power limit

High pressure at low flow

Fire retardant fluids

Stainless steel

High capacity heating

Customer specific requirements