Radial Piston Air Motors

RM110 | RM210 | RM310 | RM410 | RM510 | RM610

See Available Radial Piston Air MotorsNot Sure?

Our experienced staff are capable of selecting your air motors based on your applications and can help you make the right choice.

Please use our selection form.

Stock

We hold a vast amount of air motors and spares in stock in the UK to reduce wait times. We are a stockist and distributor of a wide selection of air motors, from the compact, handheld options to the largest 23kW piston motor. This means we can usually supply the right size motor quickly as they are readily available.

MacScott Bond holds a stock of spare parts for Globe’s pneumatic motors and has a workshop team that can offer service and repair for your motors. If you have an application that requires a pneumatic drive, please do not hesitate, and contact MacScott Bond today.

Air Motor Distributor

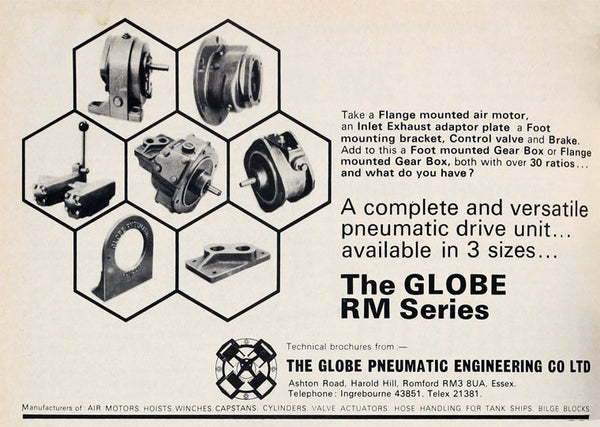

MacScott Bond has been supplying air motors in the UK since the early days of our company in the 1970s. We started representing Globe Pneumatic Engineering Company in 1977 with their Fenner air motors. Since then, we may have seen the manufacturing change over to Globe Airmotors B.V. but we still proudly support the sales and distribution of these robust air motors.

With Globe we can offer technical support on the extensive range of air motors that they have designed to ensure that you get the right motor for your application. We also hold many of the motors in stock ready for quick deliveries.